Introduction to PCB Board Fabrication

When submitting your design to a PCB fabrication factory, it is easier to submit the universal Gerber file format. Some factories do accept specific format from a particular software. You can easily generate the Gerber format of your PCB layout design through any PCB design software. Please indicate the following when submitting your PCB Gerber files to your PCB fabrication factory,

- PCB Fabrication Specification

- Quantity Required

- PCB board size (if Gerber files is not available yet)

The information will help the fabrication house to reply you with a quotation promptly. The next few section provide the details that you need to know before approaching the PCB fabrication factory.

PCB Specification Specification

The PCB fabrication specification tells us how you would like your PCB board to be produced. For simple electronic circuit (2 layer board), we will usually recommend the following commonly used industrial grade PCB specification,

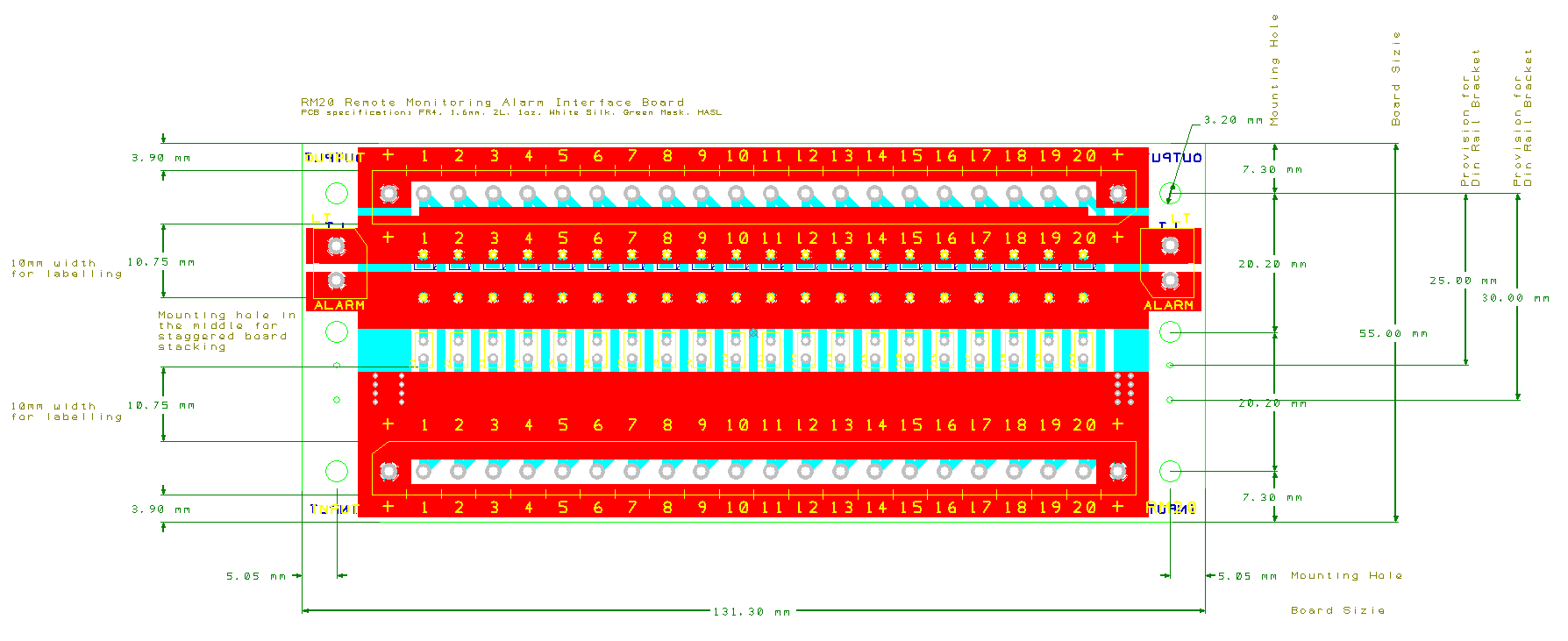

PCB specification:

FR-4, 1.6mm, 2L, 1 oz copper, Green Mask, White Silkscreen, HASL

If you would like to find out more details about the PCB specification above, check out this PCB fabrication specification page.

Quantity Required

PCB fabrication production quantity can be as low as 1 piece. As a general guide, the cost of each PCB board reduces as the quantity increase. There are works involve in setting up the machinery and process for the board production of a PCB design. You can specify the exact quantity that you need for your PCB board.

For the purpose of circuit prototyping, you may only need 1 or 2 pieces for testing. Our recommendation is to fabricate 5 pieces to cater for unforeseen rework or modification. The total cost of the fabrication job between 1-5pcs is not very significant.

A typical recommended quantity for PCB production, assembly work would be 5pcs, 10pcs, 25pcs, 50pcs, 100pcs, etc… These quantities tend to be more cost effective, in the various stage of the production process.

PCB Board Size

PCB board size is directly related to the material used. The cost for each PCB board is directly related to the cost. A bigger board will cost more than a smaller board.

Keeping the board small can help to reduce production cost and future cost (like product shipping, storage, etc…). For mass quantity production, it will make economical sense to design the board smaller.

Designing smaller PCB board can also mean a higher cost in PCB design. More thoughts and time will be needed to layout the components and traces onto a smaller board space. This higher cost in designing the PCB is usually negligible for high volume production.

Want to fabricate your PCB board?

If you have your PCB board design with your Gerber production files ready, check out our PCB fabrication service.

We are offering a standard pricing for the fabrication of your PCB prototype.

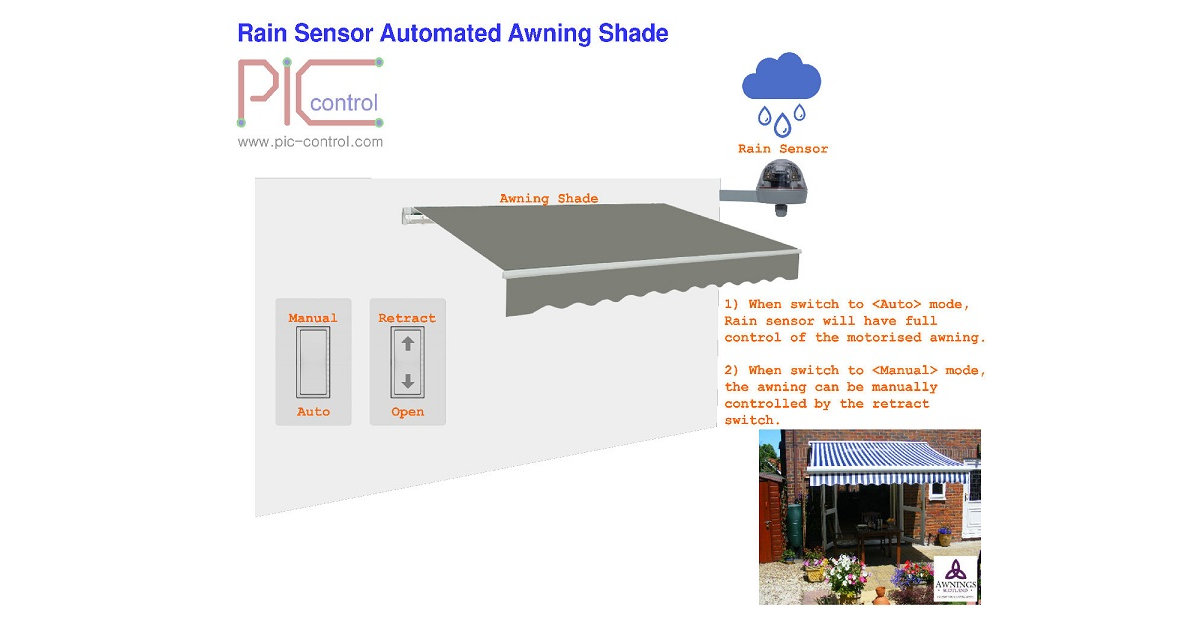

Want to design an electronic product?

PIC-CONTROL helps our client to custom design electronic product for their business. We focus on the engineering aspect providing our customers with a unique custom electronic solution. Check out these other pages for our Electronic Design or PCB Design Services.

Other Services

We provide electronic circuit assembly service and other electronic manufacturing services too. Check them out.