|

When

I first got to learn about this power saver product during an

exhibition in Singapore, I was a little bit surprise about it. The

meter measuring

the current drop instantly when this power saver thing was turned on.

The surprising part is not about its energy saving performance, but the

fact that business people is really smart. How they are able to make

use of a electrical physics to convince consumer into buying the

product.

Myself, I am trained in Electrical & Electronics Engineer for my

diploma and degree course. Although I have graduated from my university

many years back, I had little experience in the field of the 230Vac

single phase voltage system that we are using in our home. Nevertheless

I am able to recognize what I was being presented in the exhibition.

The power saver device is a scam. The purpose of dedicating this

webpage is for me to present to those who have doubt in the device, to

understand more about the power saver in a simple and experimental way.

To let you see clearer how the scam works, and how you can see the

fraud even at the exhibitor’s own setup.

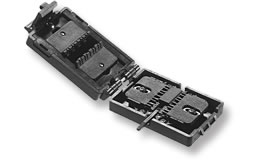

Two things in common when power saver is presented to the consumer. You

will always be presented with an instrument call ammeter (or current

meter). The appliance used in the demonstration are of inductive

property (eg. motor, fan, ballast lamp). These are the two main

ingredients that will make the presentation looks convincing for a

non-electrical trained consumer.

The ammeter was there to show the reading of the electrical current

flowing through the power cable which is connected from the mains to

the operating appliance. Higher current reading will means that more

electrical current is being drawn from the electricity power grid.

There are no tricks on this measurement, they are real. That was why

everytime when the power saver is turned on, you were able to see the

immediate drop in the electrical current. Most of the demonstration

using a clamp ammeter. The meter is clamp to either the electrical live

or neutral cable and is able to measure the magnetic field around the

cable. The intensity of the magnetic field is proportional to the

current flowing through the cable, that is why the current can be

measured. The clamp meter is easy to setup and customer can easy be

convince since the setup is clean not not hidden from the consumer’s

sight.

A

picture if the clamp-ammeter for measuring the current flowing through

your electrical appliances. Clamp the live or neutral wire of your

electrical cable to measure the current flowing. A

picture if the clamp-ammeter for measuring the current flowing through

your electrical appliances. Clamp the live or neutral wire of your

electrical cable to measure the current flowing.

The problem lies in the engineering knowledge which consumer is not

aware about. Having the current reduced does not mean that the power

consumption will be reduced. Most people will tends to link the idea of

a reduce in current, to a reduce in energy consumption. This concept

seems a bit illogical, but this is the real situation. Current and

power are not directly related. Real energy consumption is determine by

the wattage consumption, and not the current.

The actual technical terms are call real and imaginary power. They can

be quite difficult to understand and I shall simplify it by not going

too deep into the actual technical details.

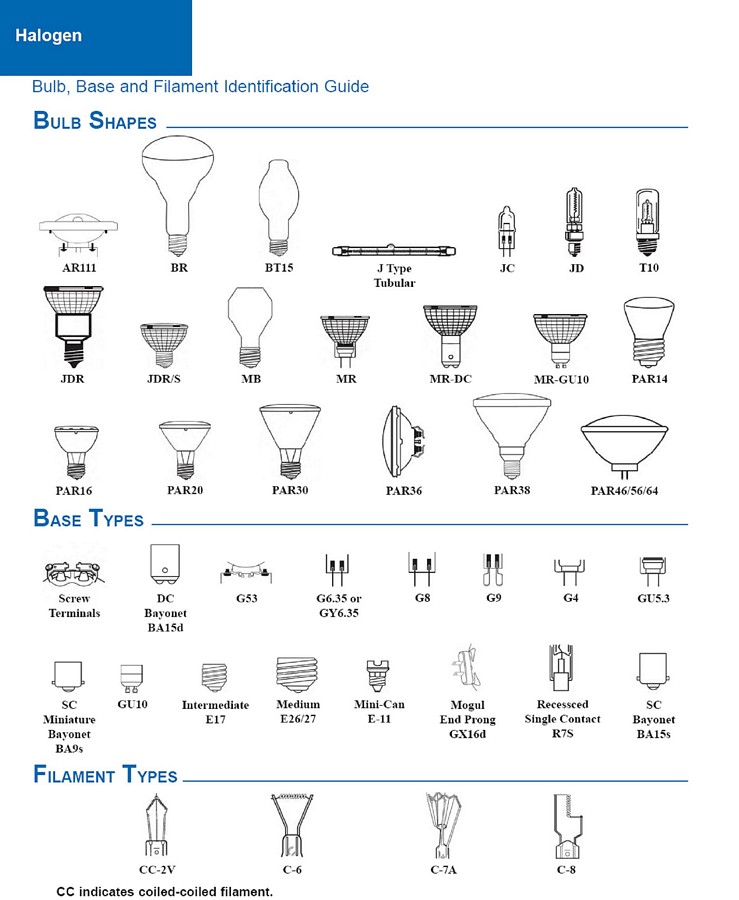

There are 3 types of load/appliances that the electrical grid will

deliver its power to. They are resistive, inductive and capacitive

load. Inductive and capacitive are technically not efficient because

extra current has to be drawn from the electrical grid in order to

support the appliances. We call these load reactive load. Assuming a

household appliance that consume 100W of power. No matter what type of

load (resistive, inductive or capacitive) this appliance might be, the

real power consumption of this appliance will be 100W. This means that

the energy consumption should remains the same regardless of the load.

Most appliances that we have at home are of resistive and inductive

nature.

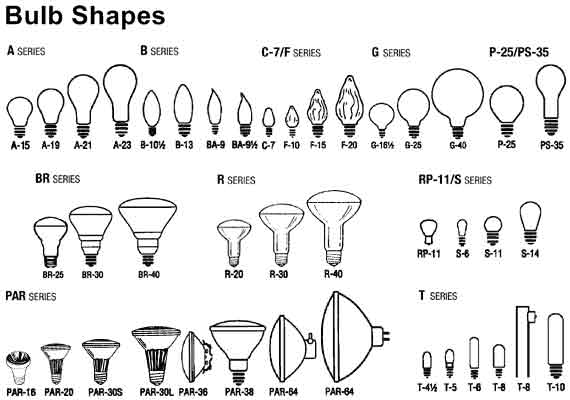

Appliances at home that are Resistive in nature are,

– hot iron

– heater

– oven

– incandescent bulb

Appliances at home that are Inductive in nature are,

– fan

– fridge

– air-con compressor

– washing machine

– vacuum cleaner

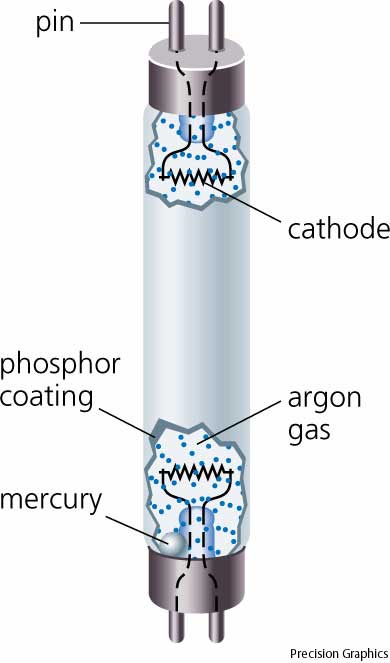

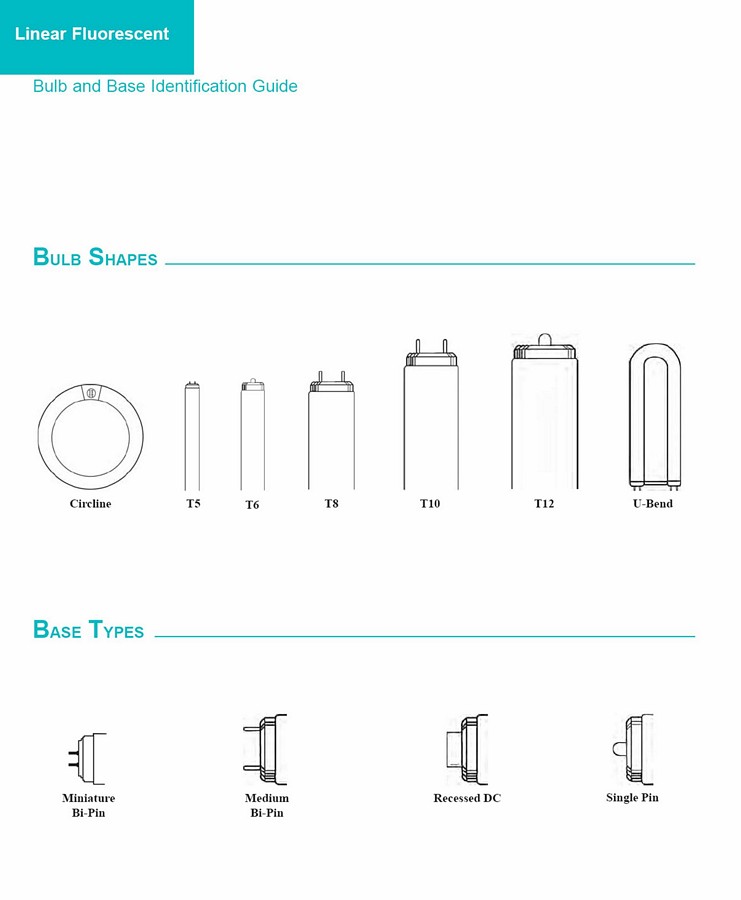

– magnetic ballast fluorescent lighting

The only thing different between the type of load, is the current being

drawn. For example this appliance is a 100W resistive load, drawing a

current of 0.4A from the grid. This 0.4A will be the lowest current

that a 100W load can go.

Example 1:

Power Supply —————————————–> 100W

Resistive Appliances

Flowing Current 0.4A

If the 100W load is now inductive or capacitive in nature, we will

expect a current reading more than 0.4A. This is because such a load

requires more current to support the load. Inductive and capacitive

load is a form of energy storage component for the electricity. The

100W inductive load though draw in more current from the power grid to

fill its storage tank, it will not consume all the energy. The unused

current will flow back to the grid. This extra in/out flow of the

current is the reason for the rise in the current that we will measured.

Example 2:

Power Supply —————————————–> 100W

Inductive Appliances

Flowing Current 0.6A

How much this extra current will be, will depend on the power factor.

Power factor ranges from 0-1. It is an indication of the load type. A

power factor of maximum 1.0 indicates a pure resistive load will have a

minimum current. A power factor of 0.0 indicates a pure capacitive or

inductive load will encounter the maximum current. Any power factor

reading between 0.0 to 1.0 means that the load is a combination of

both.

This power factor thing can be corrected like a see-saw as illustrated

below..

Power factor 0.0————————–1.0

————————–0.0

…………inductive————————resistive————————capacitive

Example 1 is a resistive load 100W 0.4A. The power factor will

definitely be 1.0 .

Example 2 is an inductive load 100W 0.6A. The power factor could be

let’s say 0.5.

The load being too much inductive with a power factor 0.5A can be

corrected by installing a capacitive counter load in parallel. The

correct capacitive load can pull up the power factor to 1.0. Too little

capacitive counter load will not pull the load fully to the balanced

power factor of 1.0. On the other hand, too much of the capacitive

counter load will make the overall load capacitive in nature and hence

power factor will also be lower than 1.0. The key to attain a power

factor of 1.0 is by using the correct counter blance load. Attain a

power factor of 1.0 will reduce the current to its minimum.

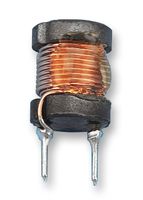

The power saver is actually a pure capacitance component inside with

its value unknown. The demonstration appliance is typically a motor or

magnetic ballast fluorescent lamp which is inductive in nature. When

the inductive appliance is turned on, the current measured will consist

of the extra current flow, therefore reading is higher. When the power

saver is turned on at the same time, the load is though balanced with a

power factor nearer to 1.0, therefore current is now lower. The closer

the counter balance is matched, the low the current will be. The lowest

current it can go will be based on its wattage as if it is a resistive

load. But it is not easy to match it to exact power factor of 1.0 for a

typical consumer.

As

what I have understood, the power service provider do not charge

consumer on the current that we have drawn, but on the real power that

we have used up. It will not be fair if they charge us base on the

current, because although we might draw higher current, we also

returned the unused portion back to the grid.

For

factory and industrial, the situation is slightly different. They will

be charged on the extra current for the reactive load that they have

introduce. Why is there such a different? This is because the

industrial ususally draw very high current from the grid. If the

current is high, the cable to support the high current has to be

thicker. If the industrial user do not correct the factor of their

manufacturing plant, it will be at the expense of the service provider

to lay more cables for them. For industrial user, they will be charged

base on the real power and the reactive power that they use. For home

consumer, our usage is quite predictable and insignificant.

So

unless your power meter measure and charges you on both the real and

reactive power, you will not need to correct the power factor for your

own house.

High current uses thicker cable. Cable not

thick enough, heat will be generated. This is a form of cable loss.

This is also how a safety fuse for electrical system works. The fuse

will burn itself if the current is too high.

But

wouldn’t that means that the cable out from the power station will be

very very thick to support the whole population? Yes, but there is

another solution. The voltage from the power station is very very high.

Given a limited cable size, we can still deliver more power to the

population by increasing the voltage. Power is the product of voltage

and current. With the limit in cable size, hence the current, we can

deliver more power by rising the voltage. That is why you can often see

electrical sub-station around the place we live in. It is a big

transformer inside which step down the very high voltage to a lower

voltage that we can use. There are many stages of sub-station from a

power station all the way to the end consumer.

You

can think of the electrical system as the distribution for our water

pipes. High voltage is similar to high pressure for the water pipe.

Cable size or current is the water pipe size. Electrical power being

the volume of the water. Having a limitation in the waterpipe size does

not means that we cannot deliver more water to the population. We can

still increase the water pressure so that the water is able to travel

faster, hence deliver more water though the pipe out.

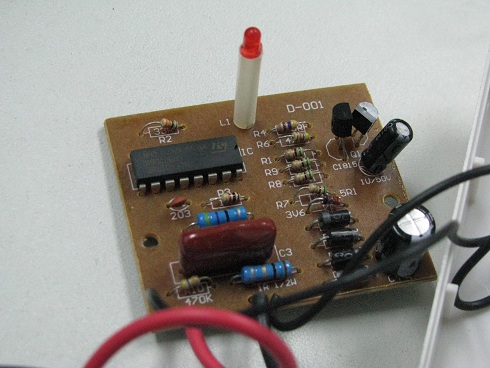

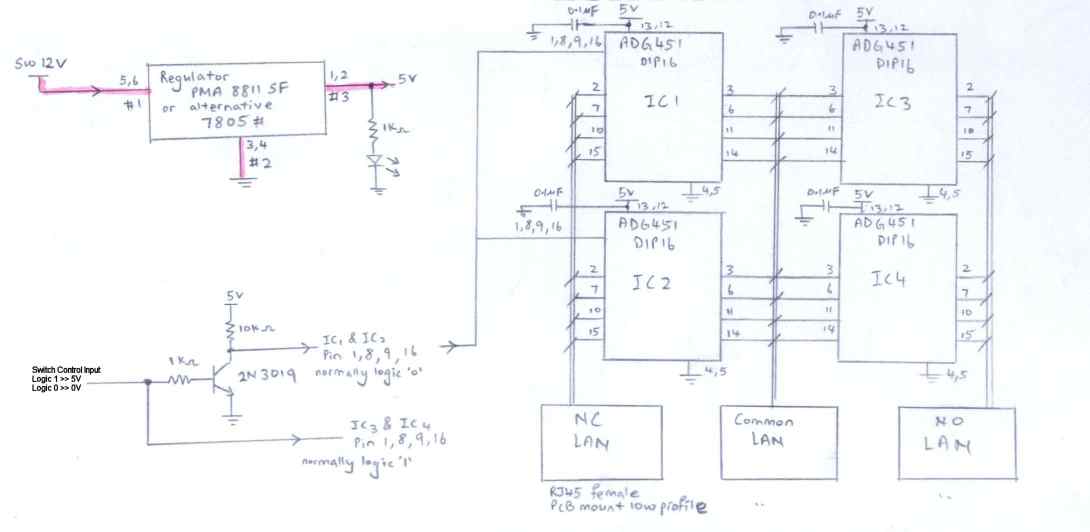

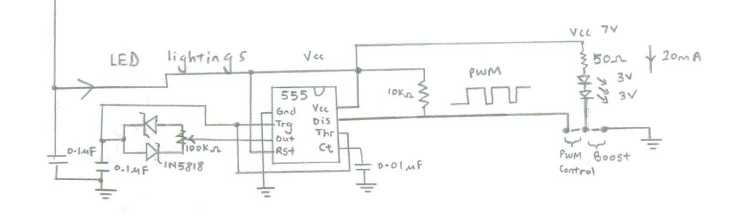

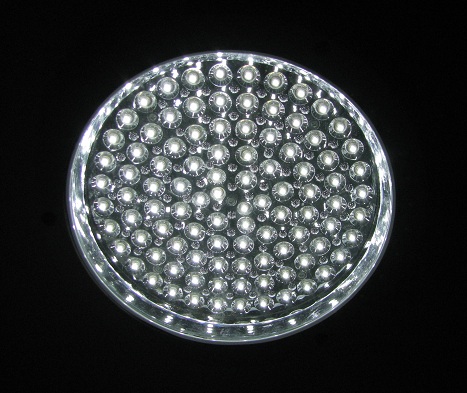

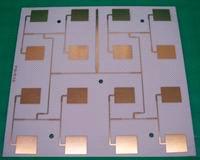

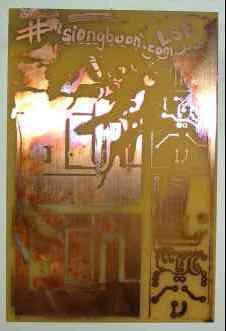

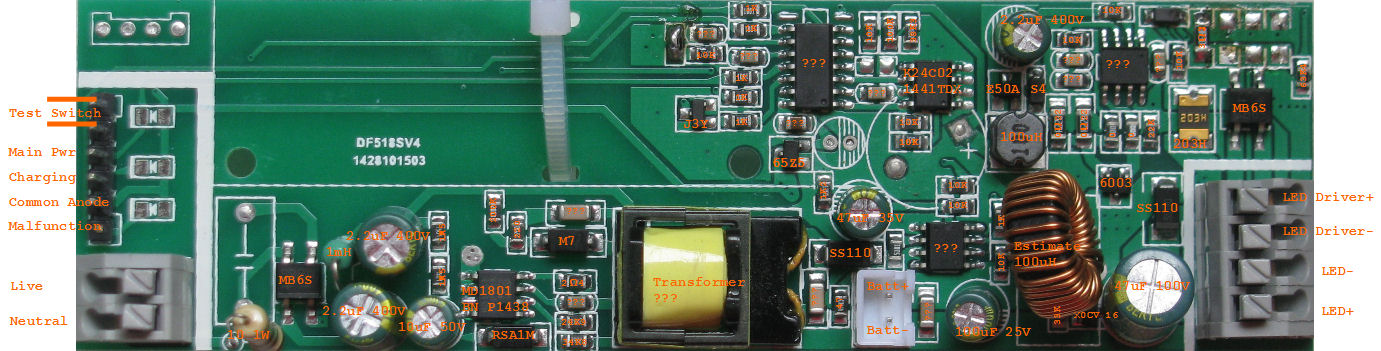

The Experiment

Now that we have know something about power factor correction, the

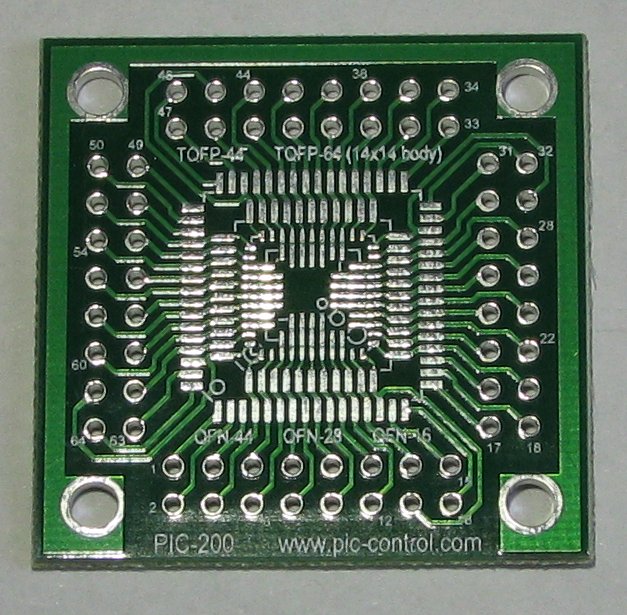

following experiment setup will further illustrate the function of a

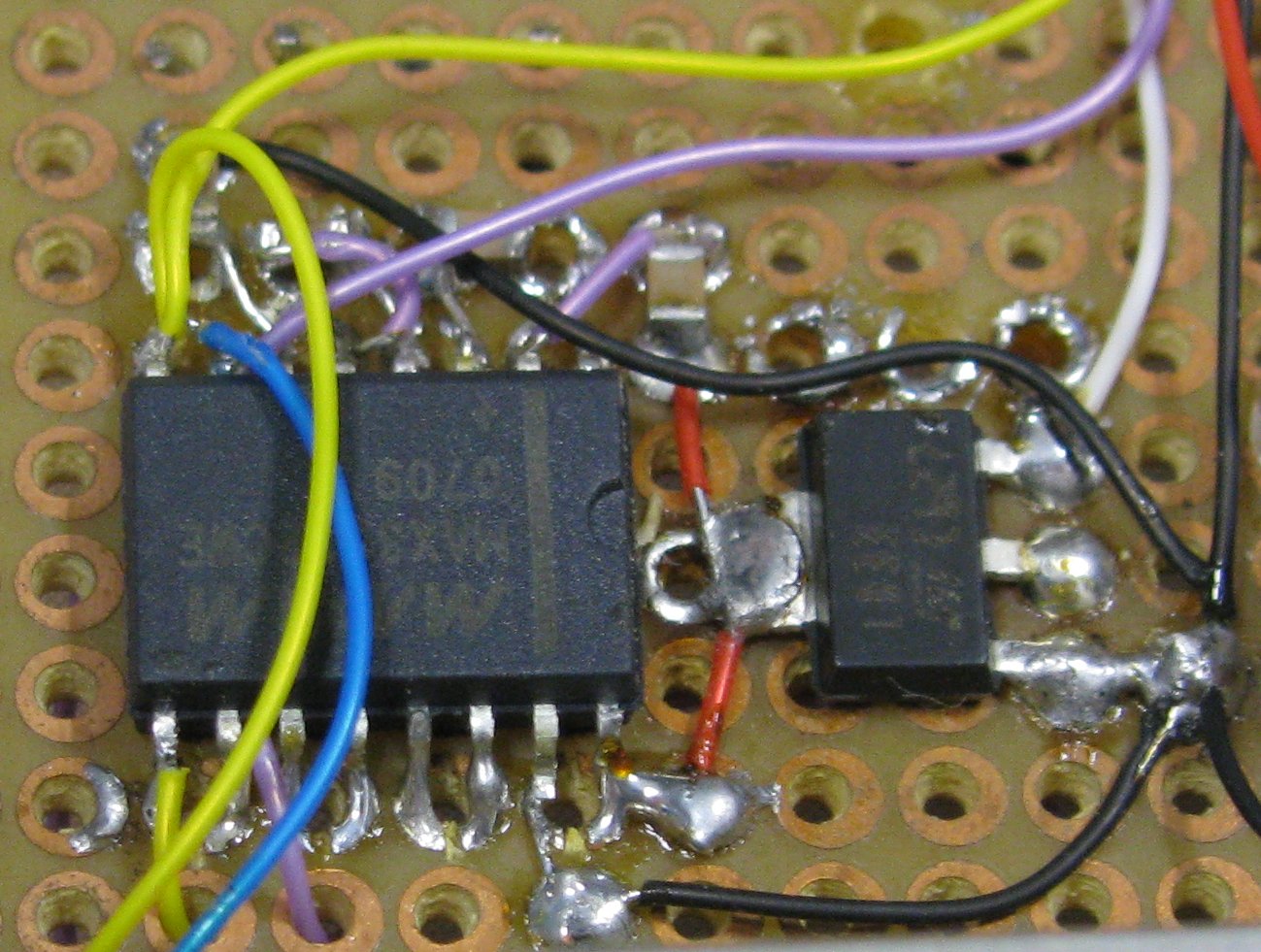

power saver and how the thing works. I have done some reverse

engineering work on the following 3 items shown in the picture consist

of (from the left)

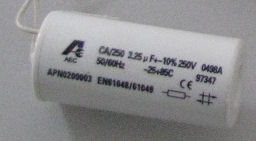

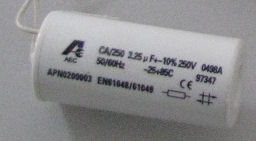

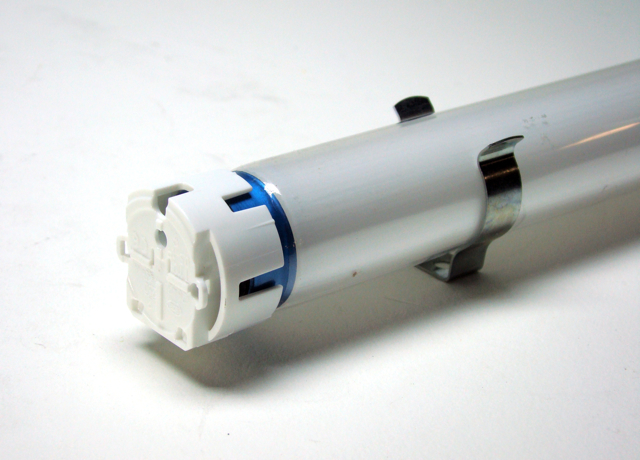

1)

I have managed to salvage white cylindrical AC capacitor from an office

fluorescent lighting using a magnetic ballast. I had remembered seeing

such component connected to the setup and have dismantled one for the

experiment. It is just an ordinary AC capacitor which electrical

contractor sometimes used to correct the power factor of the lighting

so that current flowing from the mains supply to the lamp can be

minimum. The magnetic ballast is an inductive component. Having this

counter balance capacitor load, the power factor can be improve,

therefore reduce the current. This capacitor was connected to a 3 pin

plug for the experiment. Using a multimeter, I managed to measure the

capacitance to be 3.2uF, which is the same value as labelled on the

component itself.

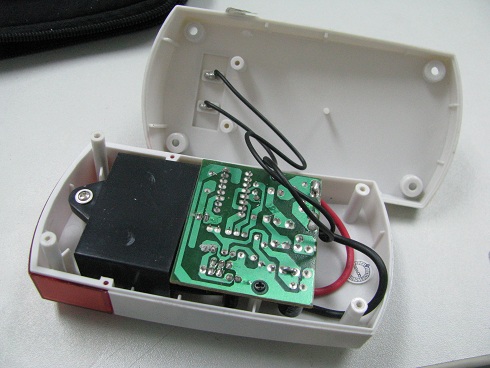

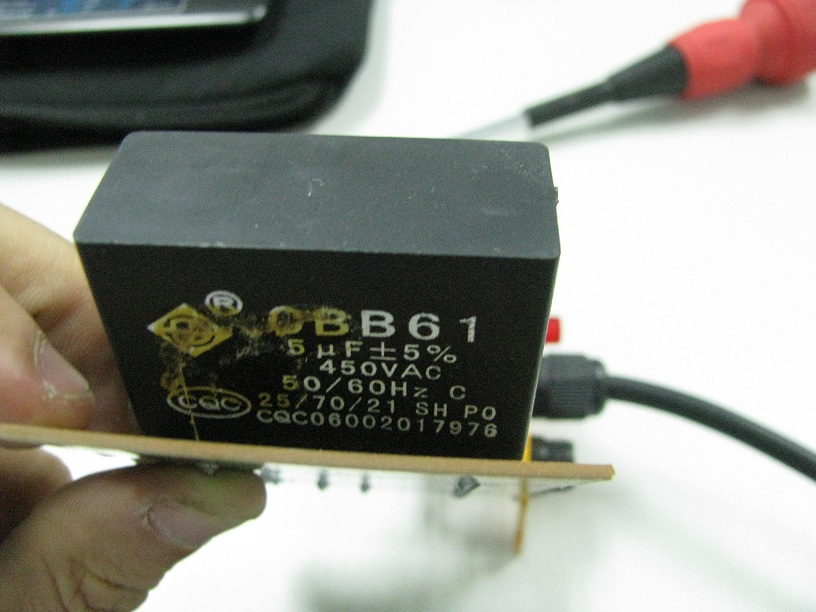

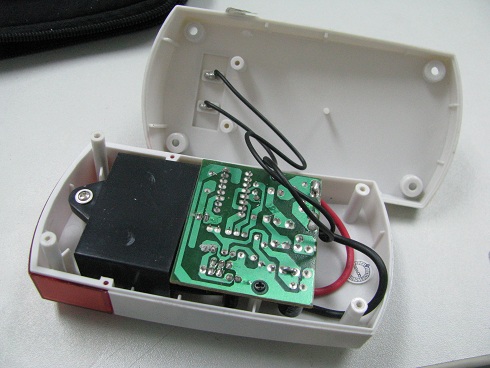

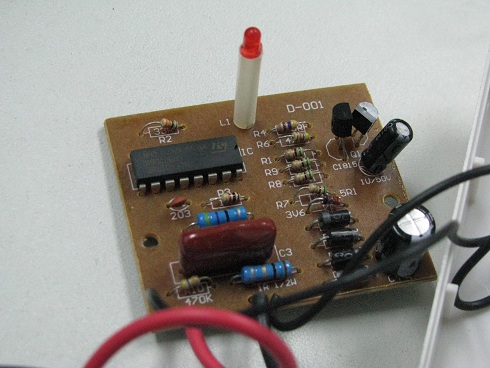

2)

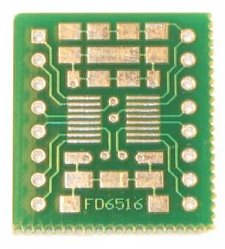

GAD1203 Extreme Power Saver (CX005). I have managed to open it up to

understand further about it’s interior. The inside consist of a circuit

and a black rectangular block. At a glance, it seems quite complicated

circuit, but after careful examination, the circuit looks suspicious.

The IC chip on-board is a logic gate IC which does not do any function.

The black box is actually a 4.75uF capacitor component. The measured

capacitance is 5.6uF which is quite close to the label. The incoming 2

pin Live and Neutral is connected parallel to the capacitor and the

circuit. Without the circuit, the capacitor will be enough to act as a

power factor correcting device.

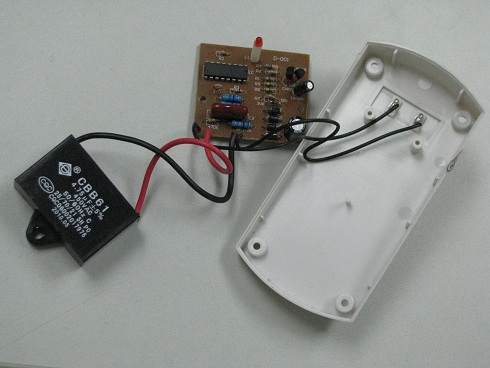

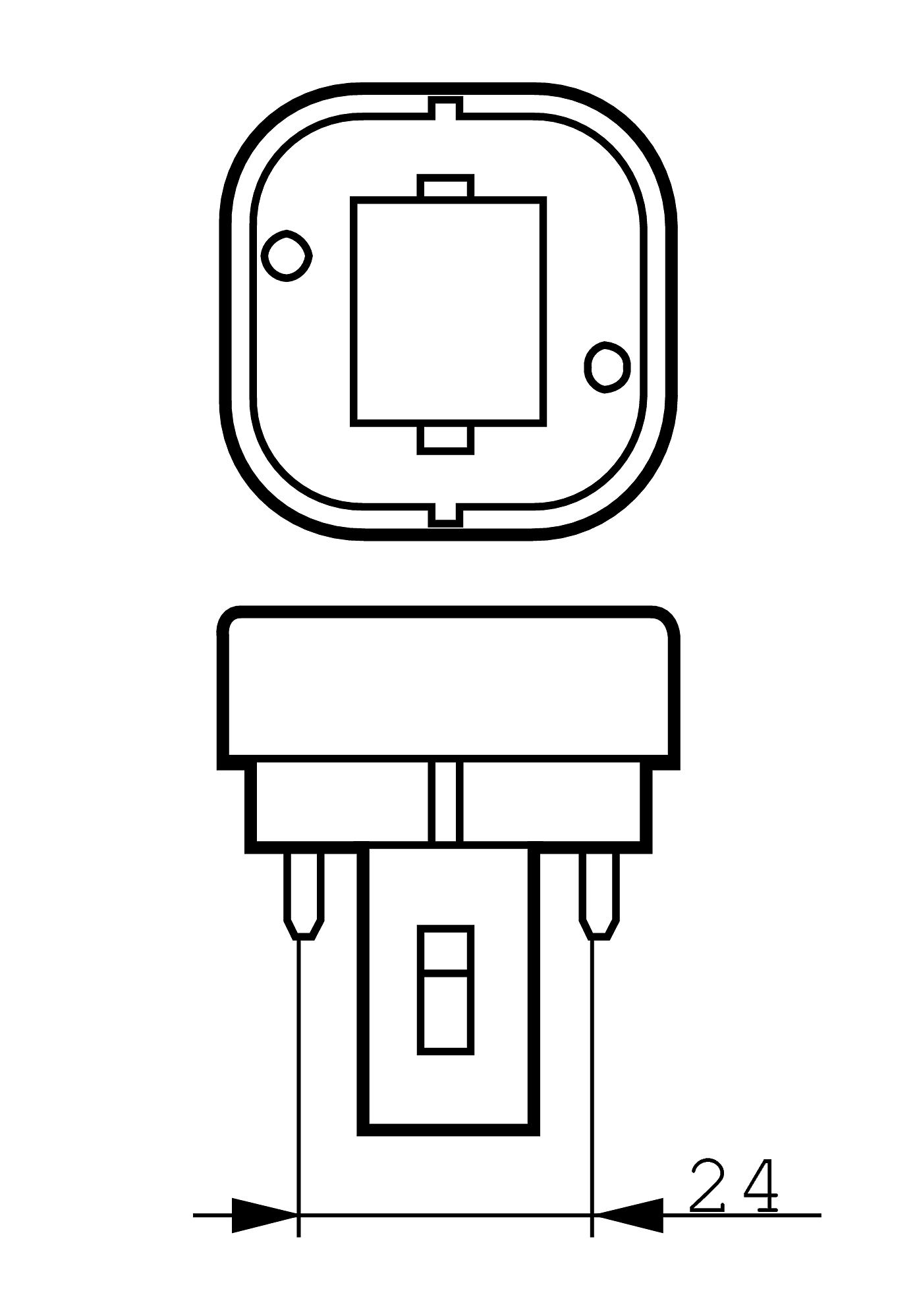

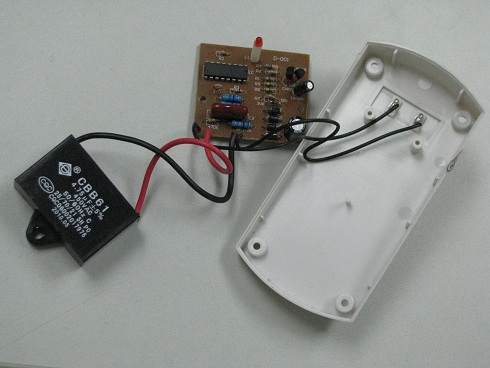

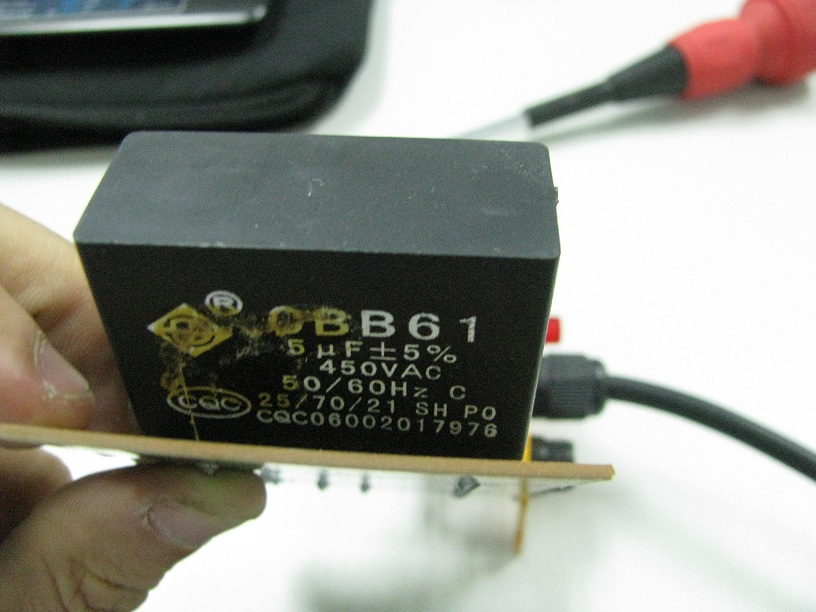

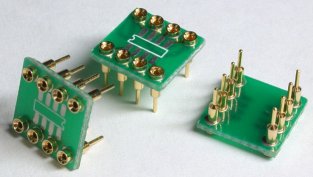

3)

GAD1202 Power Saver (CHT-001C), 2400W. This product is easier to do the

reverse engineering. It consist of two black box connected in parallel

to the AC Live & Neutral wire. The 2 black box is the capacitor

measuring 5uF each which is the same as labelled on the component

itself. Two capacitor means that the total capacitance is 10uF. There

is a lamp indicator which is connected to the AC line, indicating that

the device is connected to the AC mains.

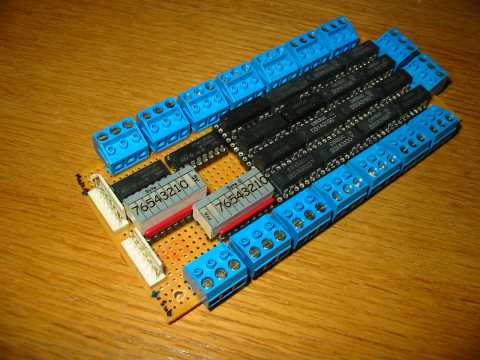

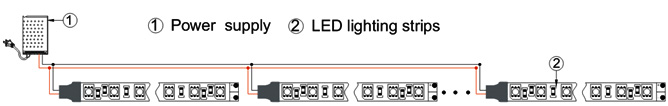

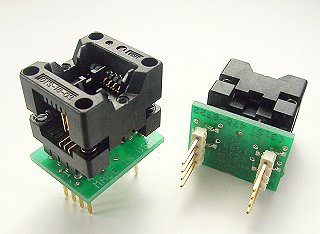

I have this experiment and

setup as below with help from saveOne Pte

Ltd

in Singapore. Their business is mainly in the Asia region Philippines,

Thailand, Malaysia and China. This company sells a range of energy

saving products, from energy saving lighting, energy saving electronic

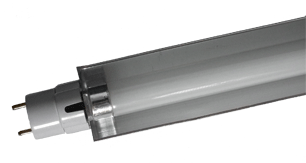

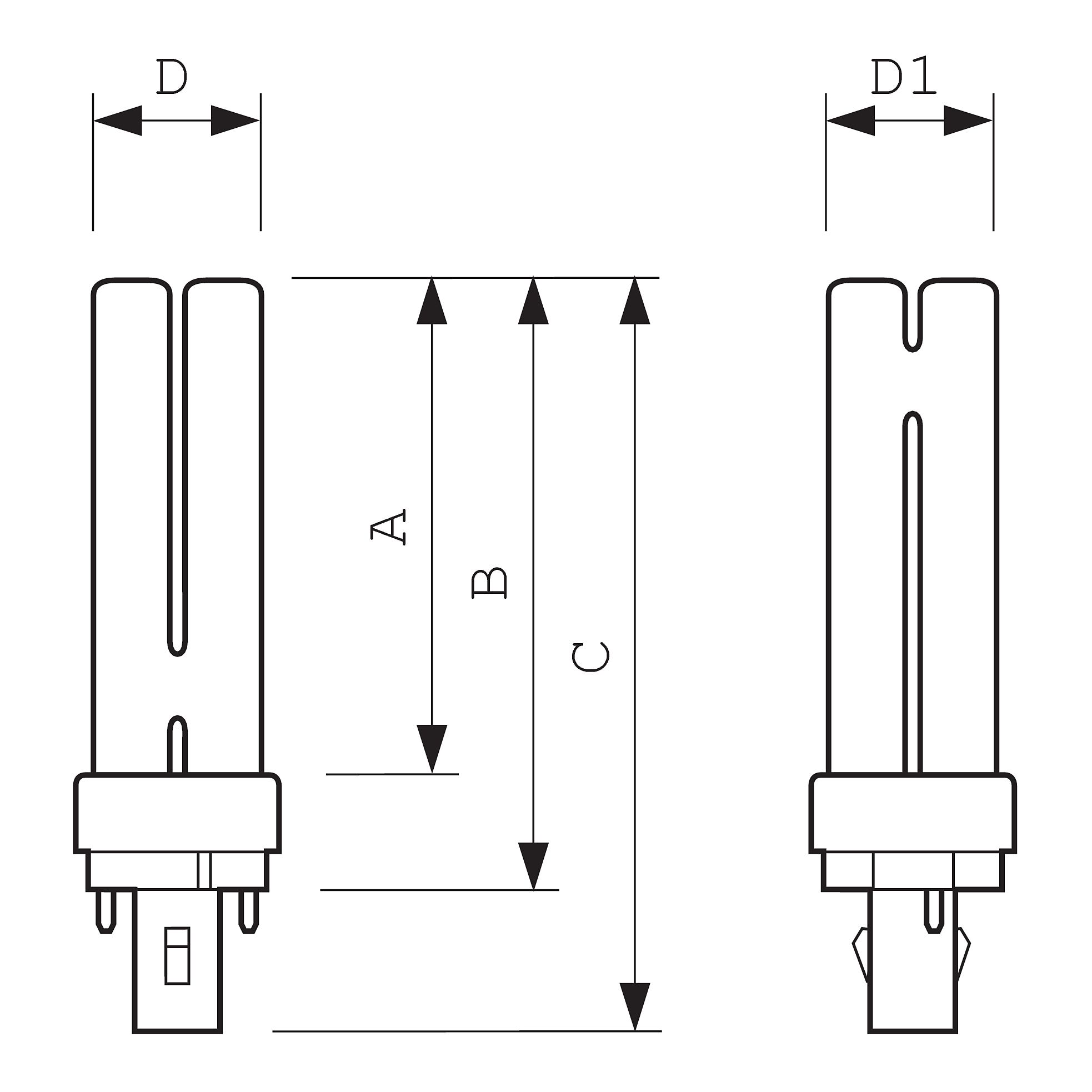

ballast to energy saving equipments. The picture shows a demonstration

rack of their electronic

ballast

product for circular fluorescent lamp which I have also installed for

my house. I like the product and have written an article about it quite

some time ago. If you are interested, you can visit this link.

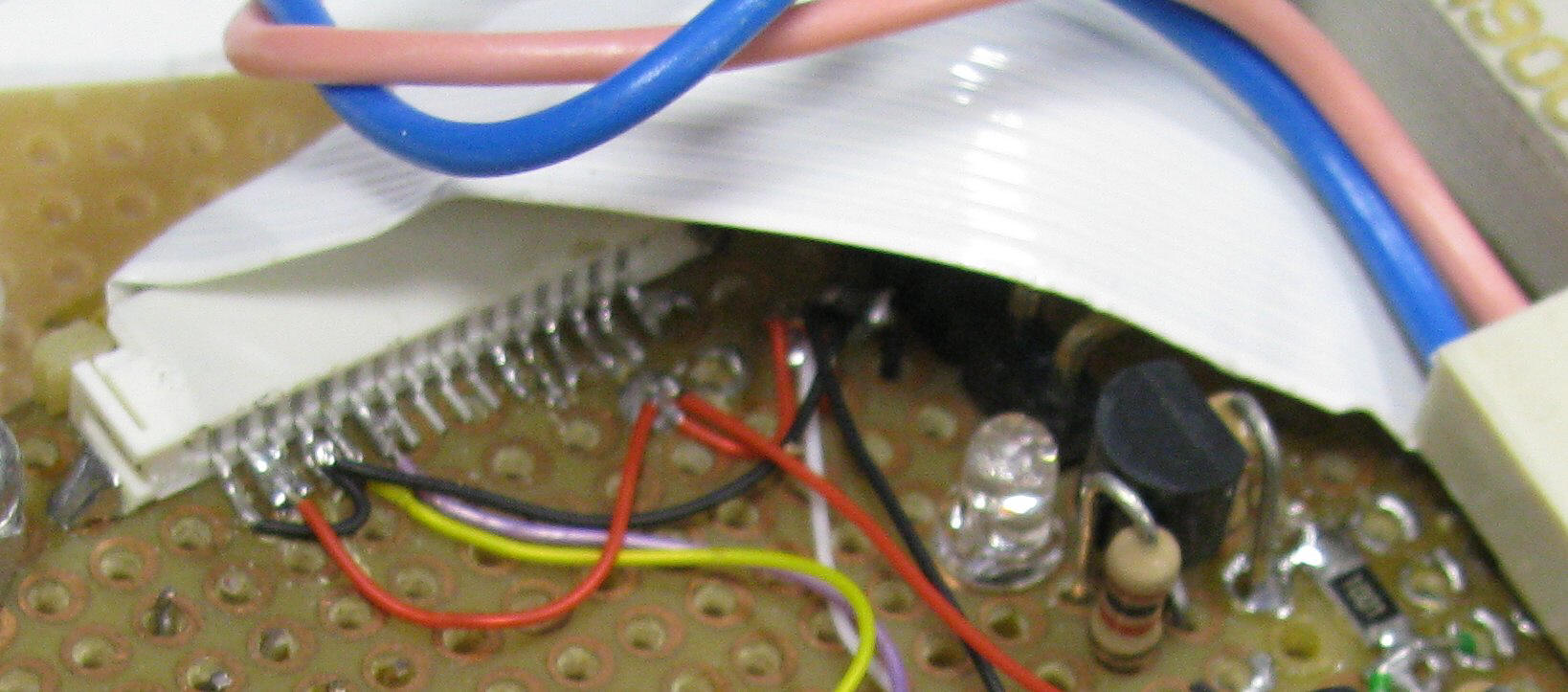

The

reason I use this rack for the experiment because there was this

magnetic ballast fluorescent lamp setup at the bottom of their rack.

You can see from the picture, it is the lamp that is lighted up.

Magnetic ballast component is an inductive load and is useful for our

experiment.

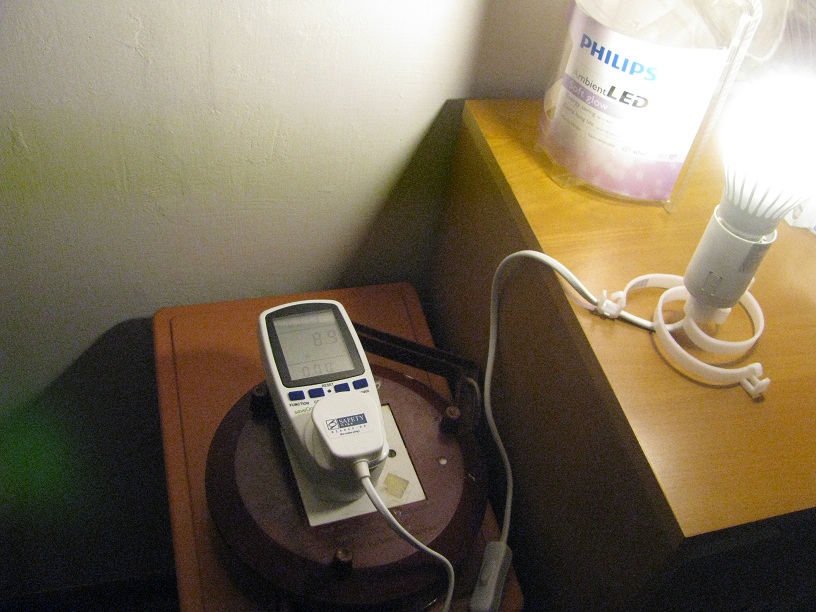

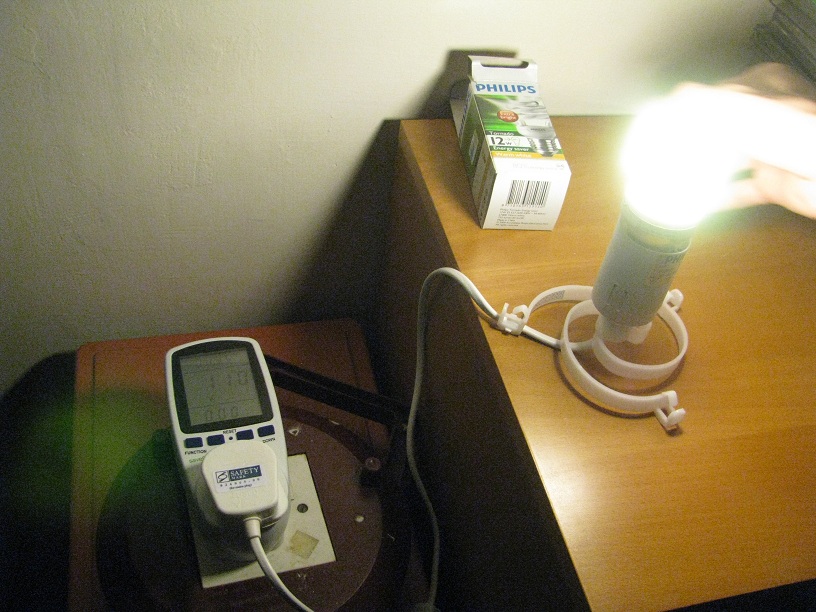

The

setup consist of 2x power meter to check on the wattage, current and

power factor at 2 location along the power supply line from the mains

to the magnetic ballast lamp. Right from the top, you can see a 4 way

socket power extension. This is the point where I would tap the power

from. The first thing that was connected is the power meter

which was connected to the 2nd socket position. This power meter no.1

measures the electricity for the whole setup. The later setup that

would be connected to this power meter will be measured. This means

that we would be able to know the current flowing from the supply mains

to this setup, and also the wattage consumption of the setup.

From

the power meter no.1, a multi-plug socket was plugged on top of it to

split the power outlet into 2. On the right side, it is where the power

saver (capacitor under test) will be plugged. The front side is the

3pin plug which is from the cable extension drum. On top of the cable

drum is power meter no.2. The magnetic ballast lamp is connected to

this power meter no.2. Power meter no.2 measures the wattage, current

and power factor for the lamp.

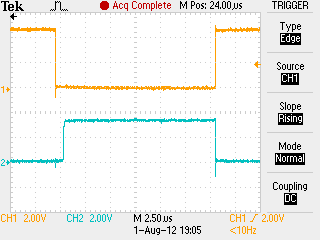

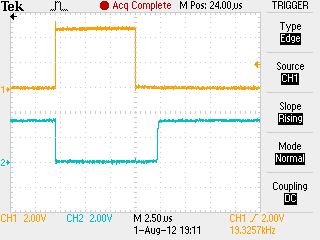

Measure Result from Power Meter no.1

| S/N |

Power Saver or

Capacitor connected |

Watt |

Current |

PF |

| 0 |

Without any capacitor connected

|

44.2W |

0.432A |

0.42 |

| 1 |

Capacitor 3.25uF ±10% 250V

|

44.2W |

0.242A |

0.76 |

| 2 |

GAD1203 Extreme Power Saver (CX005), 5.6uF

|

45.1W |

0.198A |

1.0 |

| 3 |

GAD1202 Power Saver (CHT-001C), 10uF

|

45.3W |

0.403A |

0.47 |

0.

Without any thing connected, the magnetic ballast lamp consume a

wattage of 44.2W. Current is high at 0.432A. The power factor measured

from the power meter

is low at 0.42.

1.

When the small 3.25uF capacitor is connected along the power line, the

measurement from power meter no.1 shows that the power factor has

improved to 0.76. The improve in power factor will also lead to a drop

in the current. With this small capacitor, the current is now lower at

0.242A. The power consumption remains unchanged for the own setup.

2.

Next comes the Extreme Power Saver GAD1203. The 5.6uF capacitance is

higher than the previous 3.25uF. As shown in the measurement, the power

factor is now exactly 1.0. This is a perfect match. The magnetic

ballast requires 5.6uF capacitance to correct its power factor. The

current is measured to be 0.198A. Since the power factor is perfect,

this is the lowest current we can attain for the lamp. The power

consumption goes slightly higher at 45.1W, probably due to the extra

circuit that is in the Power Saver.

3. Next comes the

GAD1202 Power Saver. The 10uF capacitance is among the highest of all

the Power Saver under this test. When it is connected along the line,

the power factor actually drop down to 0.47. This happens because we

have over correct the power factor by putting in too high a capacitance

value. The drop in power factor comes with an increase in the current

flow of 0.403A. Putting too much Power Saver can degrade the

performance. It is possible to create an even higher current than the

original setup (without any thing connected along the line). This means

that if too many Power Saver is connected along the line, you will

expect an increase in current instead. You can try it out on the

demonstration, requesting the salesman to install more Power Saver to

the setup. The current will drop up to a certain point then increase

more and more after that. The current will never drop back once the

power factor is over corrected. You will need more inductive load to

balance it back to a power factor of 1.0. I have tried it out before,

and was able to see the increase in current once the second Power Saver

was plugged in. The wattage is the highest among the rest at 45.3W.

This might be due to the lamp indicator in the circuit which will also

consume energy.

Measure Result from Power Meter no.2

Throughout

the turning on and off of the Power Saver device, the reading remains

the same. The reading is the same as the Power Meter no.1 as if no

capacitor or power saver is connected. This shows that current from the

Power Saver all the way to the inductive load (magnetic ballast

fluorescent lamp) was not corrected and still remains high at 0.432A

throughout the experiment.

Conclusion

The

current was corrected only from the power supply mains to the Power

Saver only. Current from the Power Saver to the inductive load remains

the same. In order to keep the current minimum along the cable, the

power saver will be better kept as close as possible to the load that

requires power factor correction.

The use of a power

factor correcting device helps to reduce current from the power mains

to the device. Lower current means that the current carrying AC cable

can be afford to be thinner. To put it in another way, more inductive

appliances can be connected to the same AC cable if they are all power

factor corrected. Lower current flowing through the cable also means

less power loss on the cable it self. High current flowing through a

thin cable can generate some heat (cable loss). However cable loss is

usually insignificant.

To conclude, the power saver can

help to reduce current flow. In order to reduce the current, you will

need to understand your load and apply the correct counter load value.

Over correcting an appliances will make it worst. In terms of energy

saving, the saving will be insignificant. In fact, the experiment shows

a slight increase in wattage. It is quite conclusive that the Power

Saver product is a scam.

The following are some other sites from people who have

similar knowledge and explaination. I have collected these website

for your further understanding of how power saver works.

http://www.nlcpr.com/Deceptions1.php

For alternative power saving method, you may also like to find out

about voltage trimmer from saveOne, which offers power saving

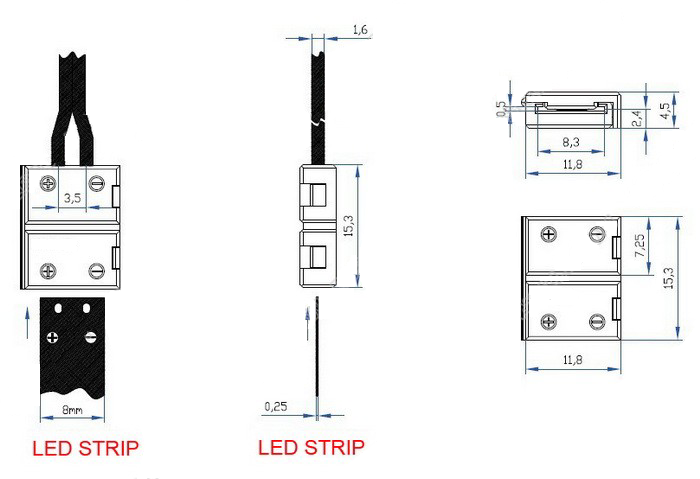

solutions. Some of their products are listed below for reference.

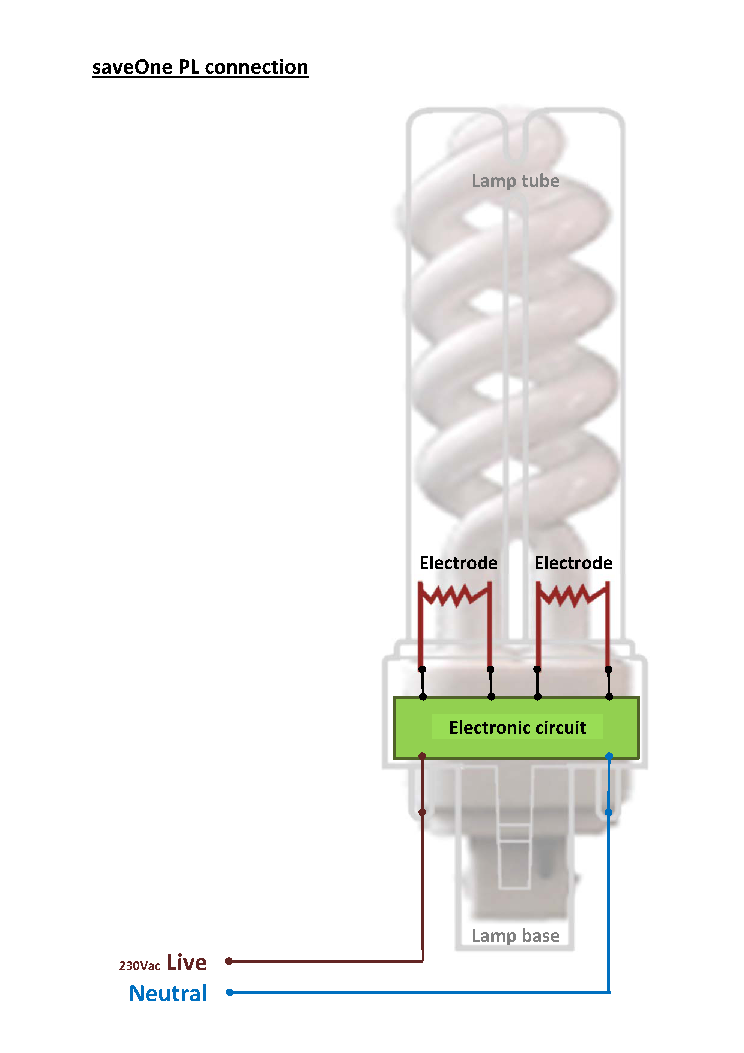

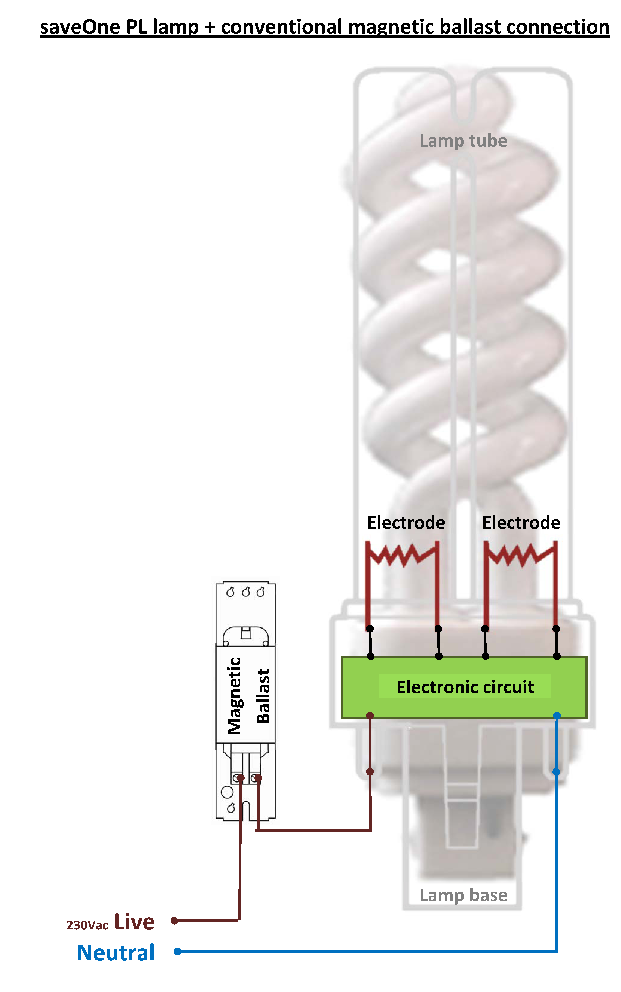

|

and a fluorescent tube

and a fluorescent tube  to work.

to work.

A

picture if the clamp-ammeter for measuring the current flowing through

your electrical appliances. Clamp the live or neutral wire of your

electrical cable to measure the current flowing.

A

picture if the clamp-ammeter for measuring the current flowing through

your electrical appliances. Clamp the live or neutral wire of your

electrical cable to measure the current flowing.

http://electricsaver1200.com

http://electricsaver1200.com

http://thepowerpanda.com

http://thepowerpanda.com

http://ecowattenergy.com/residential.php

http://ecowattenergy.com/residential.php

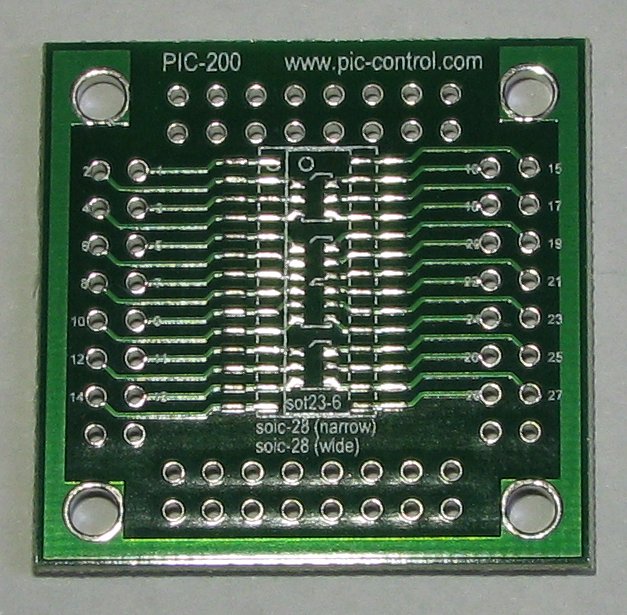

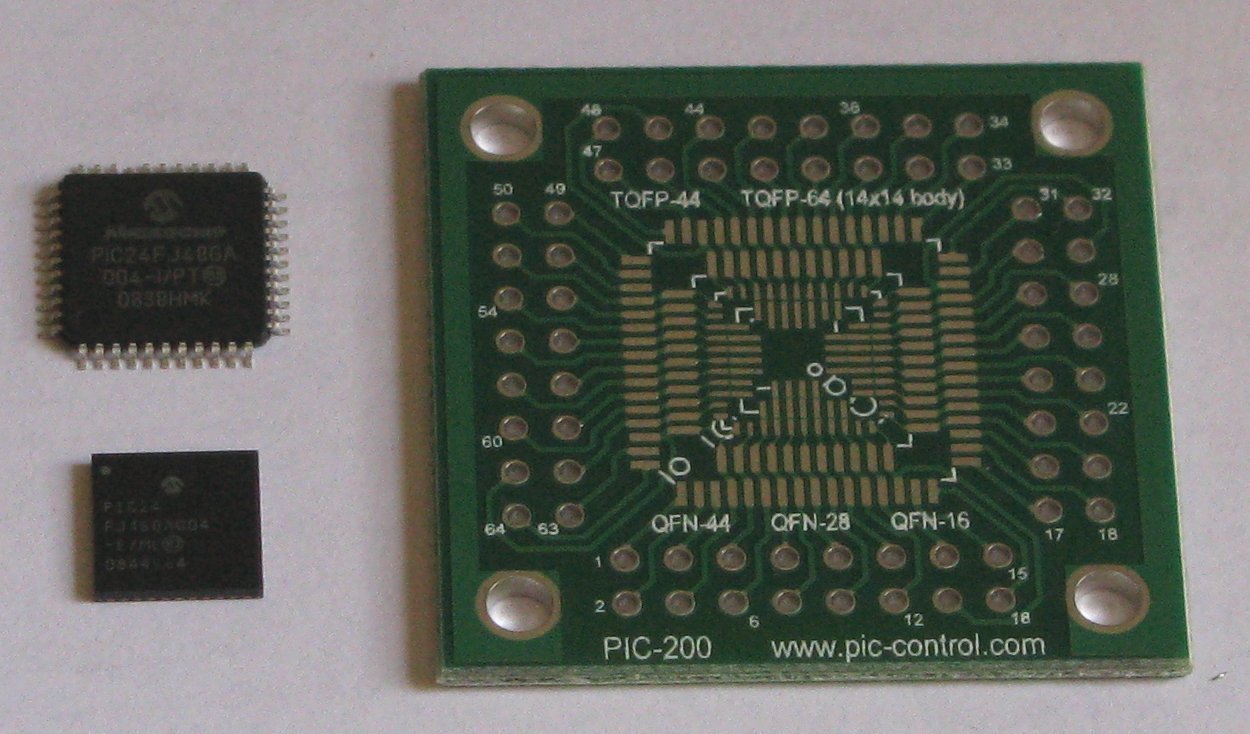

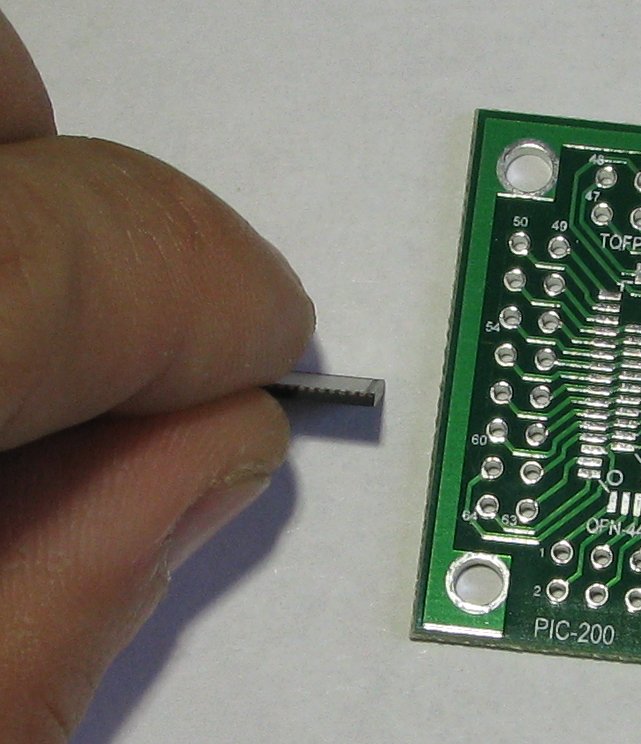

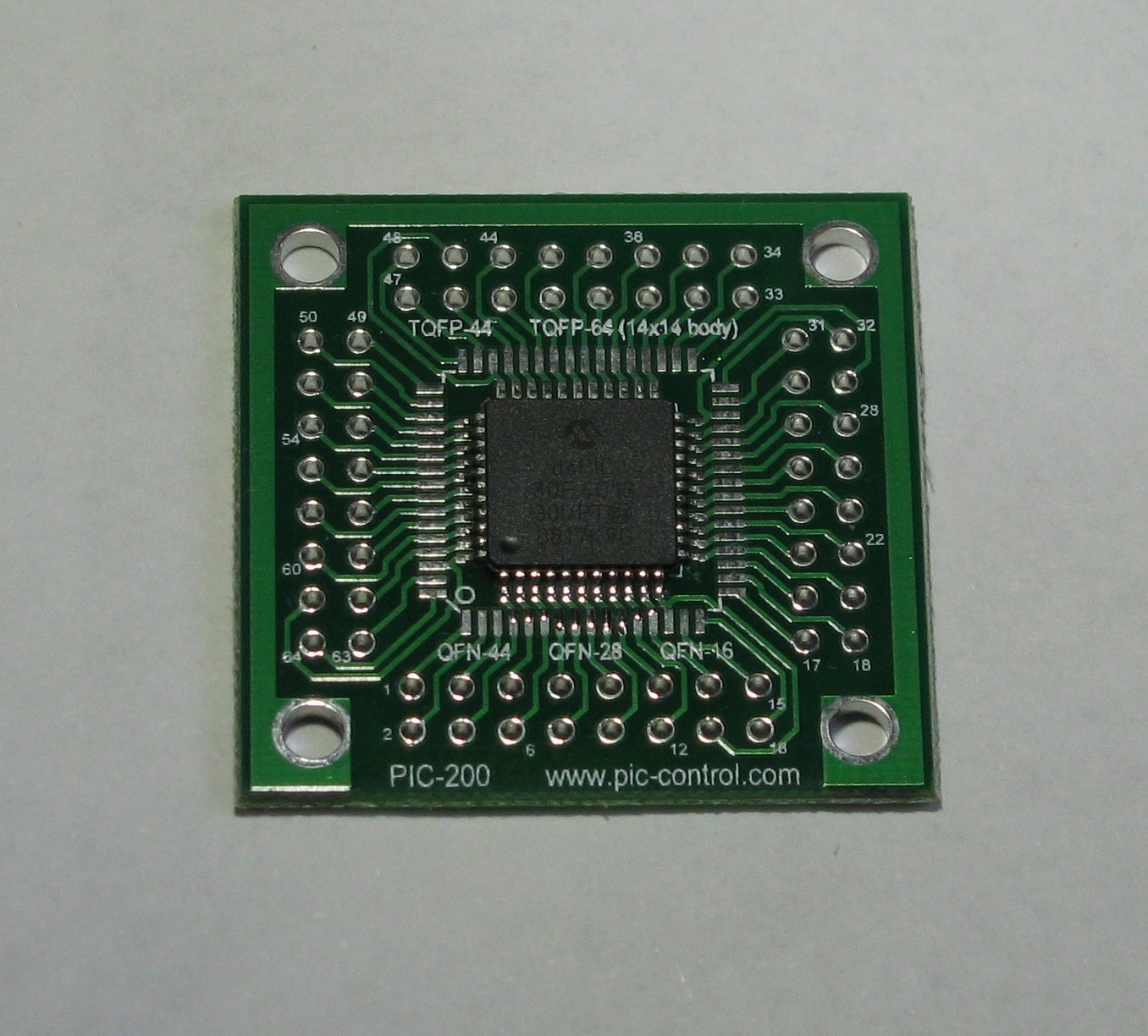

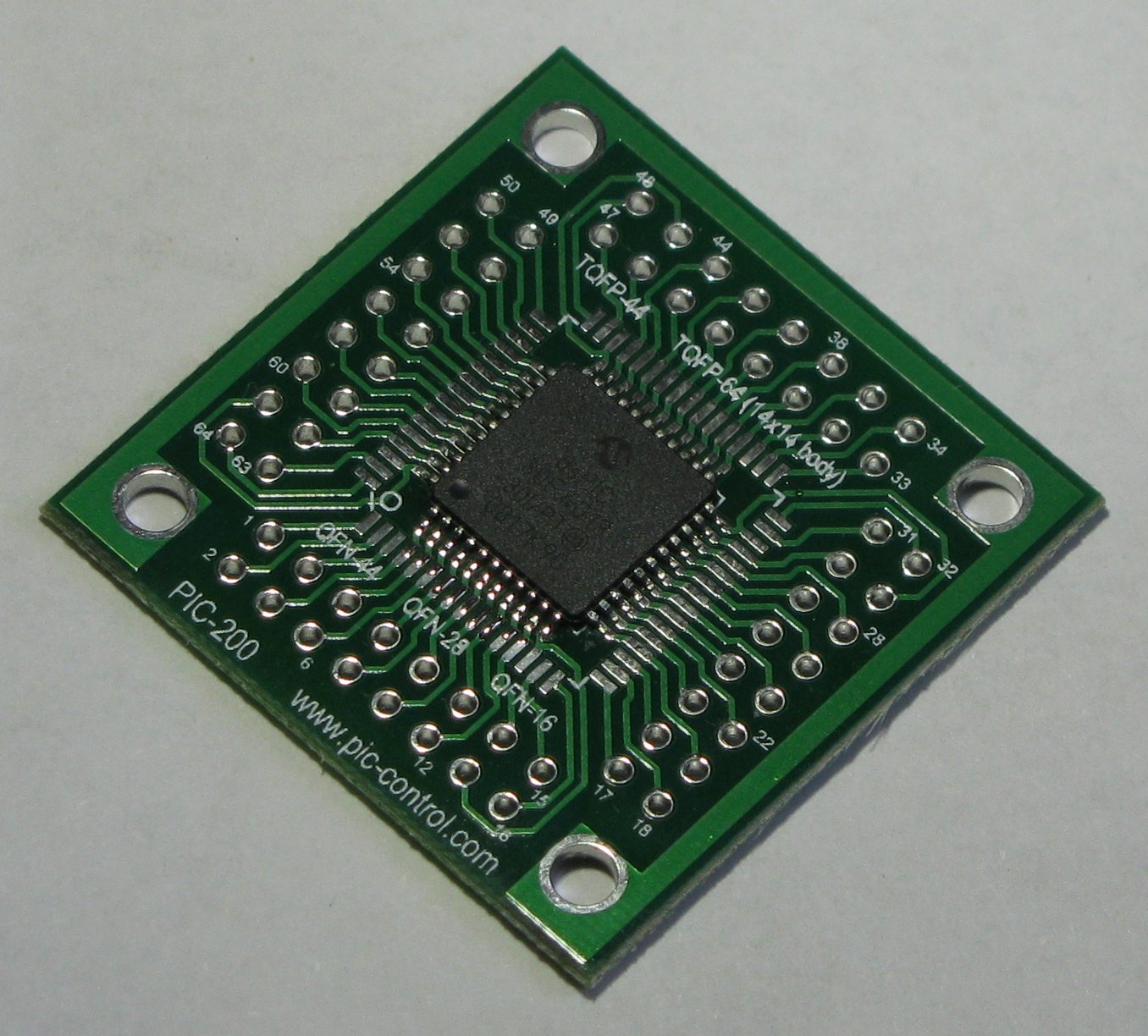

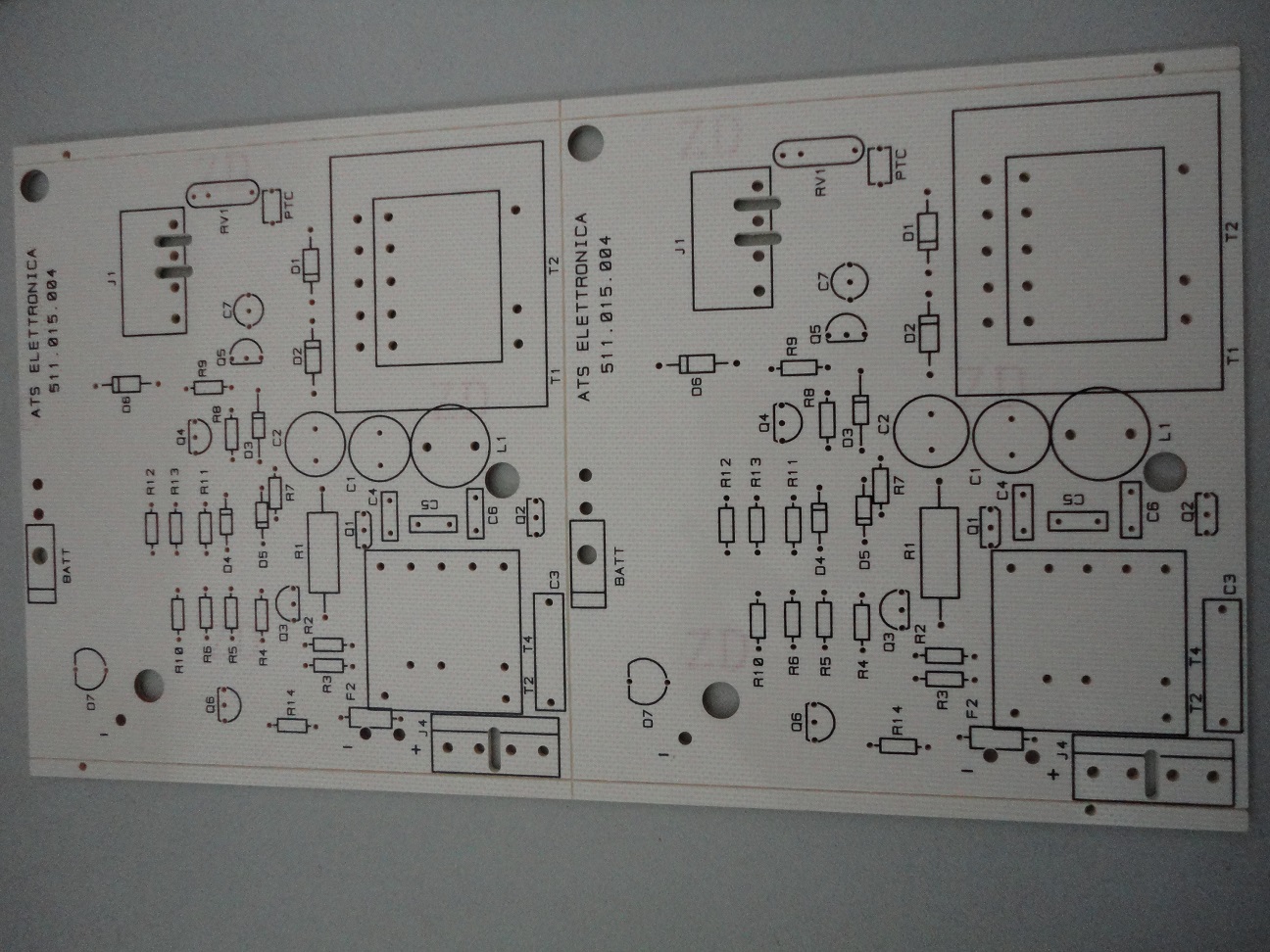

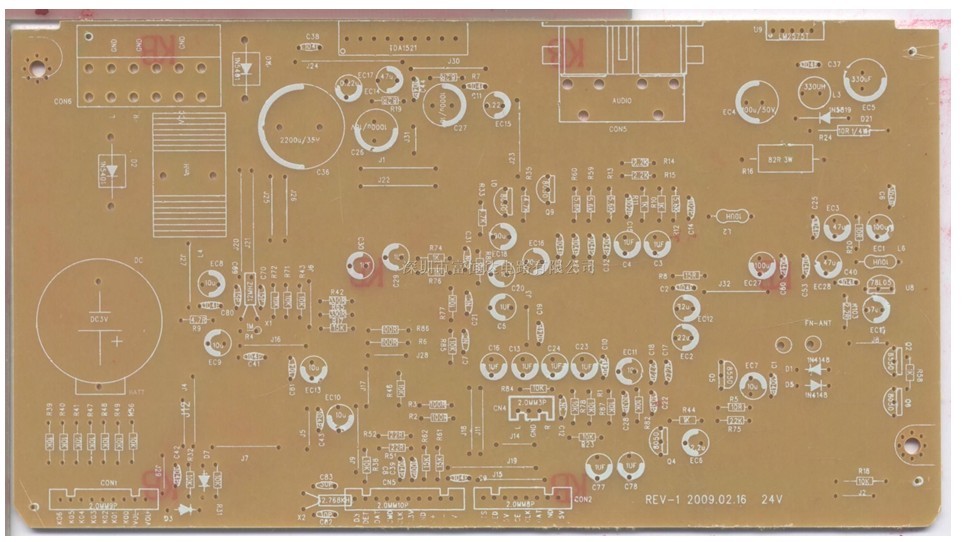

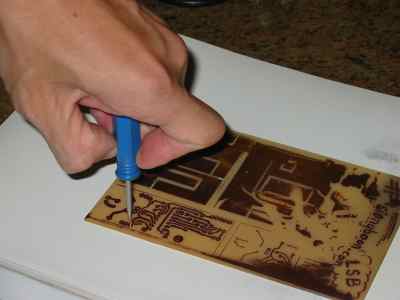

Front

Front Back

Back

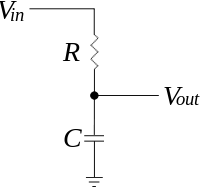

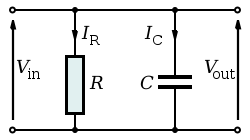

RC filter, the simplest low pass filter.

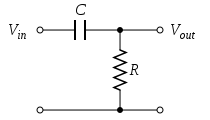

RC filter, the simplest low pass filter. Another way of looking at the same RC filter.

Another way of looking at the same RC filter.  A capacitor as a low pass filter.

A capacitor as a low pass filter. RC filter, the simplest high pass filter.

RC filter, the simplest high pass filter.

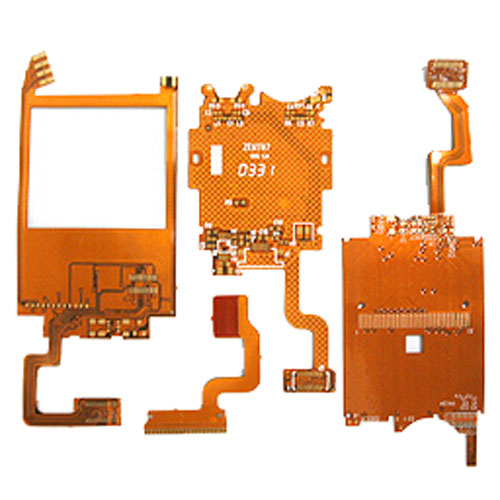

A

phone small enough to carry around.

A

phone small enough to carry around.

Mobile

phone as thin as biscuit.

Mobile

phone as thin as biscuit.

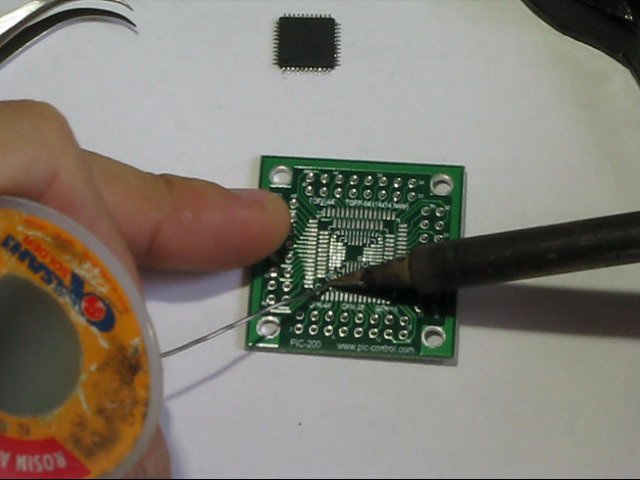

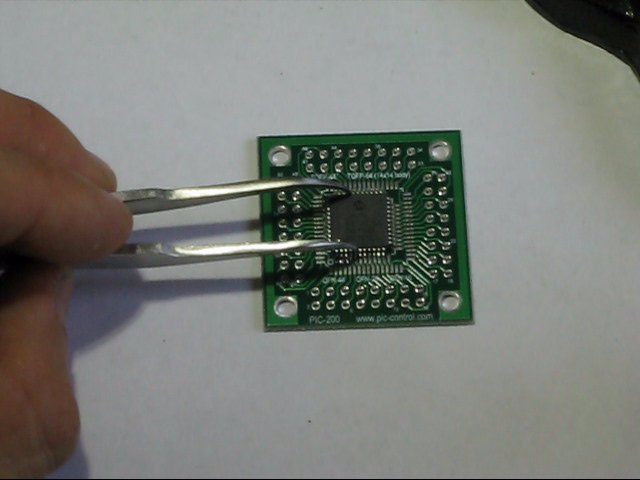

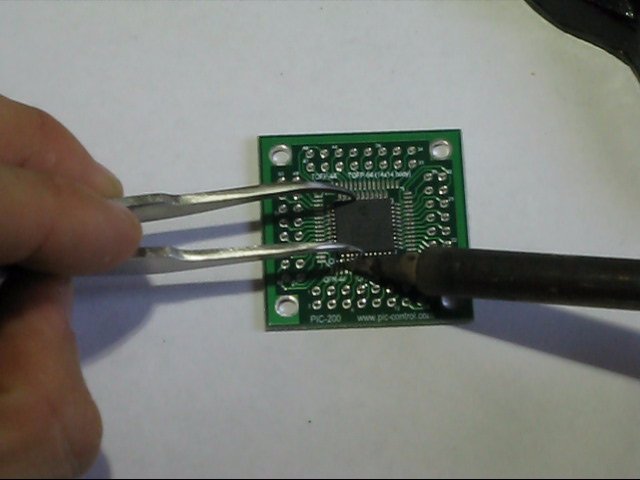

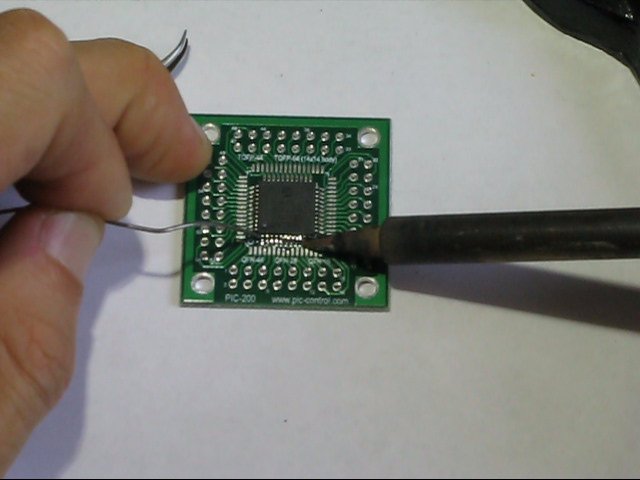

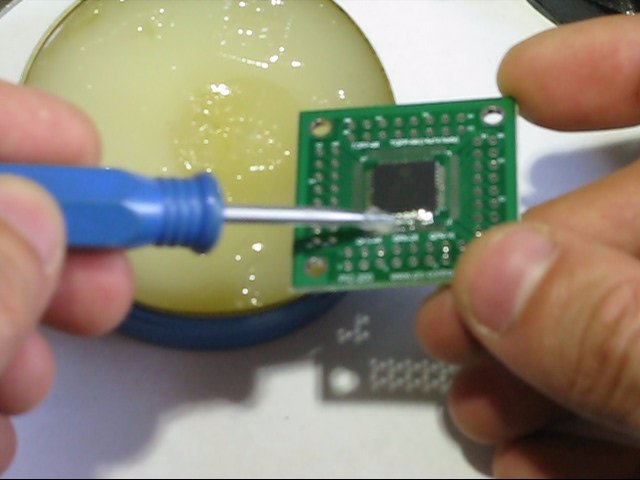

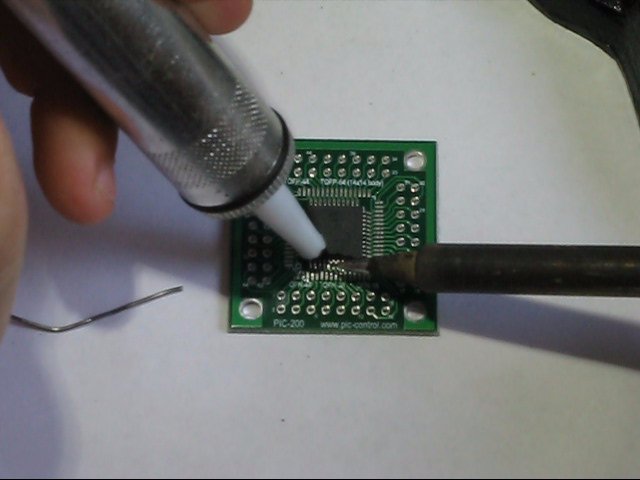

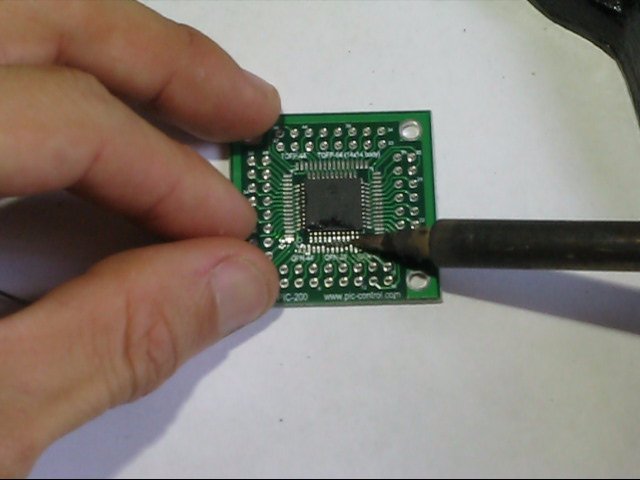

Rework Station

Rework Station

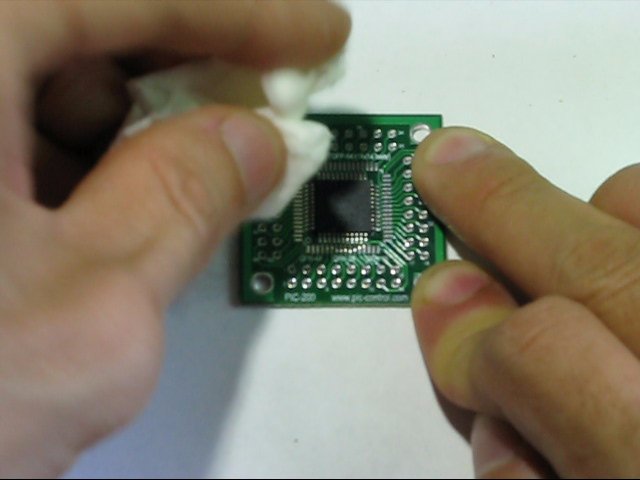

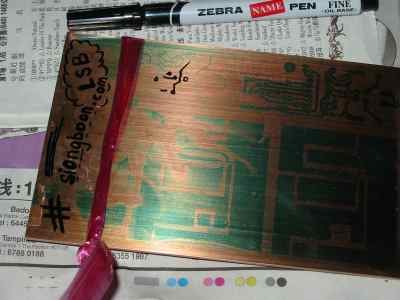

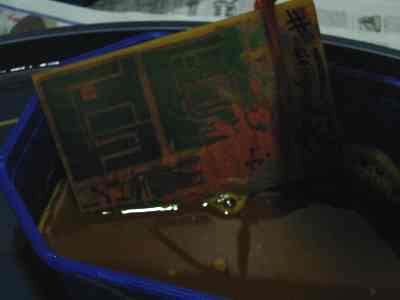

Alcohol

& thinner has a lower flash point, and catch fire easily. You have to be

extremely in handling and storing these flammable chemical. Do not store or

work on the chemical near electrical appliances, hot area or things that can

cause spark. Keep your windows open to allow air to circulate while working

with these chemical. They may cause headache, dizziness and uncomfortable

when inhaled.

Alcohol

& thinner has a lower flash point, and catch fire easily. You have to be

extremely in handling and storing these flammable chemical. Do not store or

work on the chemical near electrical appliances, hot area or things that can

cause spark. Keep your windows open to allow air to circulate while working

with these chemical. They may cause headache, dizziness and uncomfortable

when inhaled.

ultra-violet exposure

ultra-violet exposure

When mixing

NaOH to water, heat will be produce. Stir the water solution constantly

while adding in NaOH slowly.

When mixing

NaOH to water, heat will be produce. Stir the water solution constantly

while adding in NaOH slowly.

tinned PCB board.

tinned PCB board.

Cross Reference next to the search box, type the part number and search:

Cross Reference next to the search box, type the part number and search: